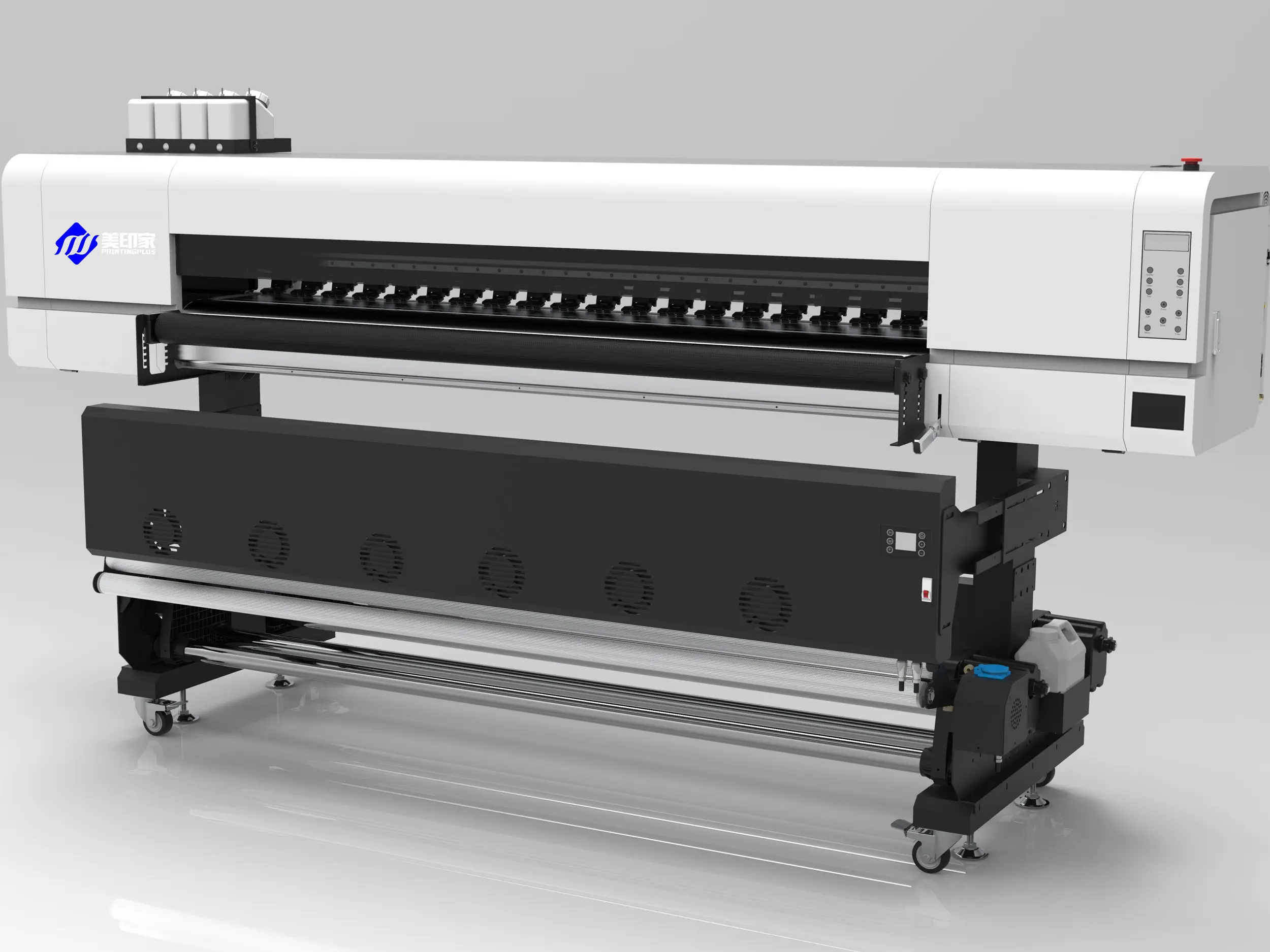

Dye Sublimation Printer for Shirts - - PRINTINGPLUS

Product details of the dye sublimation printer for shirts

Product Description

The raw materials of PRINTINGPLUS dye sublimation printer for shirts is purchased by a professional team. The superior material makes the product superb in quality. Our QC team monitor procedure as per quality system requirements.

THE FUTURE OF Dye Sublimation Printer

- As a typical clean production printing and dyeing process, digital printing has been recognized and adopted by major enterprises, and has become the primary choice to replace traditional printing. As an emerging printing method, with its advantages of high efficiency, low proofing cost, good printing effect and less pollution, it meets the increasingly diverse needs of the market and brings unprecedented development opportunities to the textile industry.

Power 100-4800W

Product Description

- Thermal sublimation ink is thermal transfer ink, is the low energy, easy to sublimate disperse dyes made into digital printing ink, printed on the transfer paper, through heating, you can fill the image in the shortest time to fine porcelain, metal, silk, chemical fiber cloth and other materials, very suitable for personalized development of the market needs and environmental requirements.

To put it simply, the sublimation ink is printed on a specific paper in advance, and then through the paper, with the high temperature and high pressure, the pattern on the paper is transferred to the printed cloth to complete the whole transfer printing process.

Product Details

- Digital printing has environmental protection and energy saving, fast delivery, suitable for batch flexibility

- Double inflatable shaft

- The double inflatable shaft gives the machine a stable retracting and retracting paper, so as to ensure exquisite printing and efficient production

- High capacity cartridges

- The use of two level ink supply system, long-term printing ink, to ensure the quality of the screen output

- Drying system

Drying design, drying system intelligent synchronous printing, safe and efficient, so that printing dry worry-free.

Product Characteristics

- Achieve intelligence, high efficiency, high quality

Application

- Product application Garment fabric / hometextile / towel roll / rug piece / footcloth / carpet

FAQ

The target market of our brand has been continuously developed over the years. For more information, please reach our team, we are more than happy to help.

Company Advantage

• PRINTINGPLUS's location enjoys traffic convenience, complete facilities and good comprehensive environment. All these are good for the efficient transportation of br /> • Our company has a complete talents project. Based on that, we have gathered a group of elite talents with rich industry experience. They are proficient in production, sales, service and brand marketing.

• PRINTINGPLUS's sale market covers the whole country. The products are also exported to Southeast Asia, Africa, and other countries and regions.

PRINTINGPLUS supplies directly from the factory at a favorable price. We are sincerely looking forward to your consultation and long-term partnership. We could create a better tomorrow together.