Wireless Dye Sublimation Printer - - PRINTINGPLUS

Heat Transfer Printer - An Efficient Solution for Clothing Printing

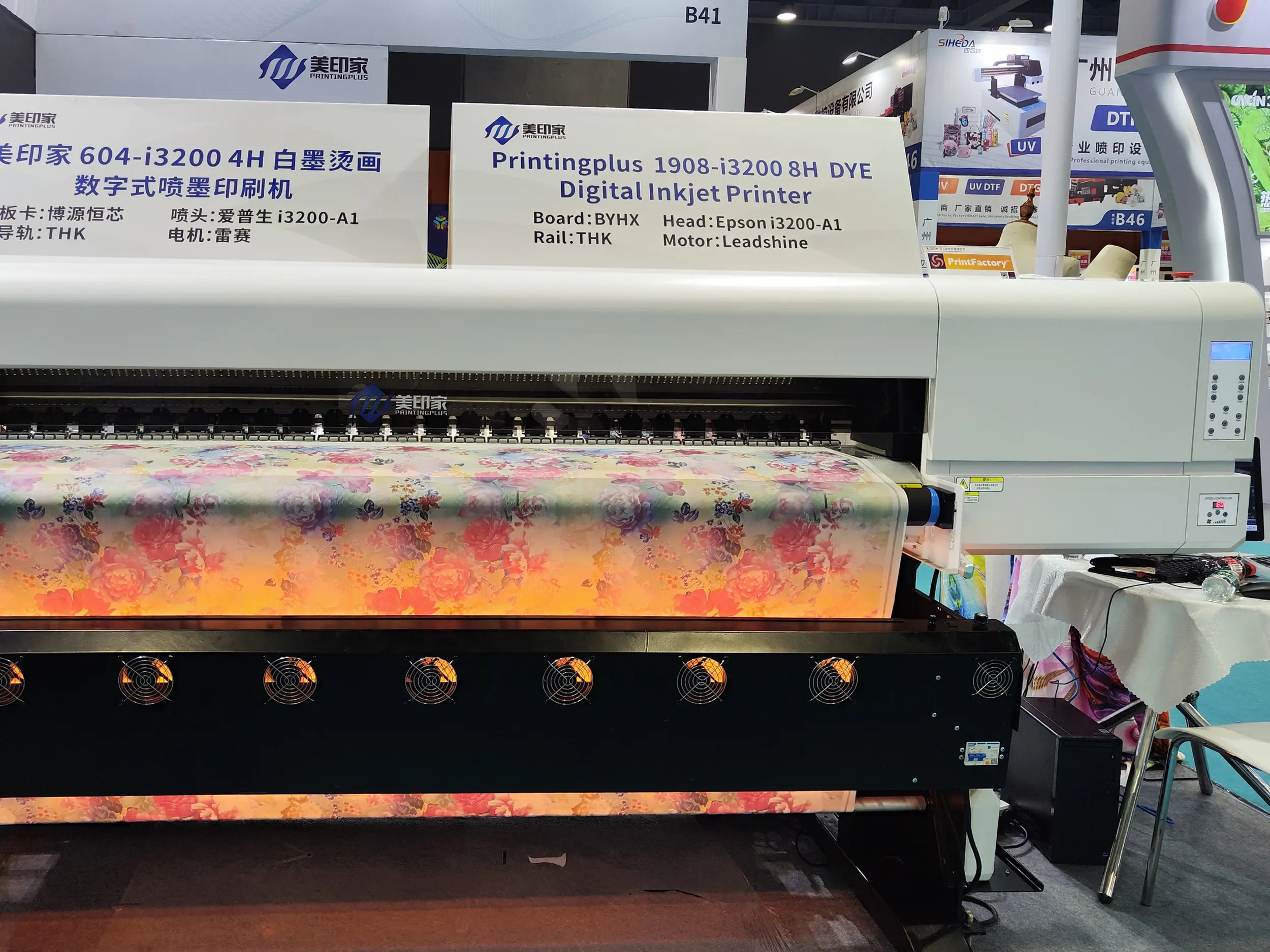

The heat transfer printer is a digital printing device specially designed for textiles and flexible materials, with a width of 1.9 meters. It is equipped with Epson i3200 printheads and supports CMYK four-color output. Combined with heat transfer paper and high-temperature heat pressing technology, the printed patterns are rich in color and soft to the touch. The machine body is made of thick steel plate structure and is equipped with a double air expansion shaft paper feeding and take-up system to ensure smooth paper feeding.

Fast Transfer, Economical and Efficient

Product Advantages

The thermal transfer printer combines digital inkjet and heat press technology, featuring a simple production process that can be operated by a single person. It supports high-precision printing with natural color transitions. The transferred products are washable and stretchable without cracking. Equipped with a dual air expansion shaft paper feeding and rewinding system, it has minimal paper deviation and no line breaks during continuous printing, offering a much higher cost performance than traditional screen printing.

Product Details

• Dual ink supply system

3L large-capacity ink cartridge with built-in dual filters to reduce ink impurities and ensure stable ink supply without bubbles.

• Anti-curl edge presser bar

Presser bars are added on both sides of the platform to keep the paper flat and reduce print deviation.

• Intelligent temperature control module

Real-time monitoring of the heating plate temperature, automatic power-off in case of over-temperature, safe and reliable.

Advantages of Heat Transfer Printing

The heat transfer printing process does not require complex pretreatment. After printing, high-temperature heat pressing can complete the transfer, and the efficiency is higher than that of manual printing. Using heat transfer ink, it is non-toxic and odorless, and the environmental protection index reaches grade A. The finished product is soft and breathable, suitable for various fabrics such as cotton, polyester, and blended fabrics, and the pattern remains intact after washing.

Application

Leading the New Trend in Clothing Printing

Heat transfer printers are widely used in the printing of T-shirts, sweatshirts, curtains and other textile products, supporting complex patterns and gradient color designs. They are suitable for customizing trendy clothing and home textiles. The finished products have a soft hand feel and help brands quickly capture the market.

FAQ

The target market of our brand has been continuously developed over the years. For more information, please reach our team, we are more than happy to help.

Company Advantages

· The production of PRINTINGPLUS wireless dye sublimation printer complies with relevant laws and regulations.

· The quality of the product has been greatly assured by our complete quality control system.

· PRINTINGPLUS has constructed a relatively complete wireless dye sublimation printer process line to ensure the quality.

Company Features

· As a pioneer in the wireless dye sublimation printer field in China, Guangzhou Honytek Printing Technology Co.,Ltd is steadily expanding into a broader overseas market.

· Our company has a trained and well-educated workforce. Keeping up to date on the trends in the wireless dye sublimation printer industry, they can always offer the best recommendations and insights to clients and prospects.

· Guangzhou Honytek Printing Technology Co.,Ltd perseveres in urging the office cooperation culture. Contact us!

Application of the Product

wireless dye sublimation printer developed and produced by PRINTINGPLUS is widely applied to many industries and fields. It can fully meet the diversified needs of customers.

With rich manufacturing experience and strong production strength, PRINTINGPLUS is able to provide professional solutions according to customers' actual needs.