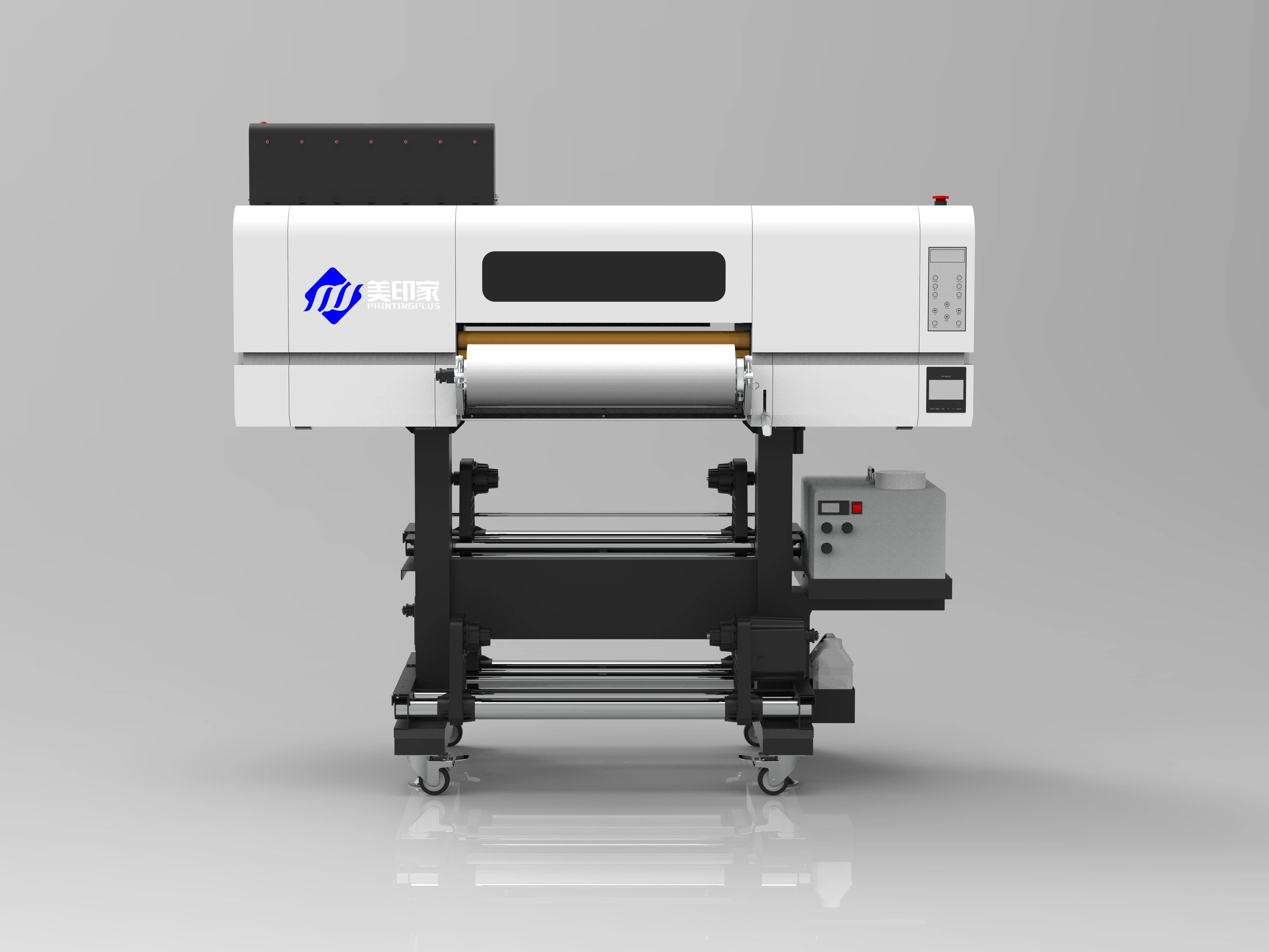

Print coated roll integrated 4 standard UV crystal printer

Product Details

UV lamp curing principle refers to a chemical or physical reaction process that uses ultraviolet radiation to harden or solidify substances. Therefore, for some products containing UV sensitive materials (such as some glue, paint, paint, tape, etc.), the curing of UV lamps can accelerate the reaction speed, improve the production efficiency, reduce the cost and optimize the product performance.

Product Highlight

Product parameter

|

Print resolution/speed |

4pass:9.6m2/hour 6pass:6.3m2/hour 8pass:4.7m2/hour |

|

Ink type |

CMYK + White + varnish |

|

High Printing quality |

Three intelligent eclosion print function:VSD technology |

|

RIP Software |

Maintop6.1 |

|

Net weight of equipment |

220 KG |

|

Table height/Height of Worktable |

1066MM |

|

Gross weight |

240 KG |

|

Maximum width |

62CM |

|

Powder |

AC110V+/-10%、AC220V+/-10%、50/60+/HZ |

|

Operating ambient humidity |

35%RH-65%RH |

|

Operation Envrionments |

Temperatur:20℃-35℃ |

|

|

AB film/PET film |

|

Dimensions of Packing |

L 2082 x W 800 x H 1820 MM |

|

Dimensions |

L 2220 x W 1310 x H 1836 MM |

Professional Features

Production process

1. Pattern design, and typesetting

2. PET Film

3. White color oil synchronous output and printing

4. Print is complete, samples are randomly attached to the items

Product application

With the development of science and technology, the improvement of life quality and the continuous diversification of aesthetics, the demand for labels is increasingly diversified. It was at such moments that the crystal symbol developed. Crystal label with its unique three-dimensional, crystal, hollow, rich color, delicate image, convenient paste advantages, has been widely used. All kinds of bags, glass art, tea packaging box labels, handicrafts, wood, plastic, sports equipment, helmets and so on can be easily reprinted and sticky.

faq

Preparation Before Shipment

● 100% Inspection of Shipment

● One-Site Testing And Commissioning