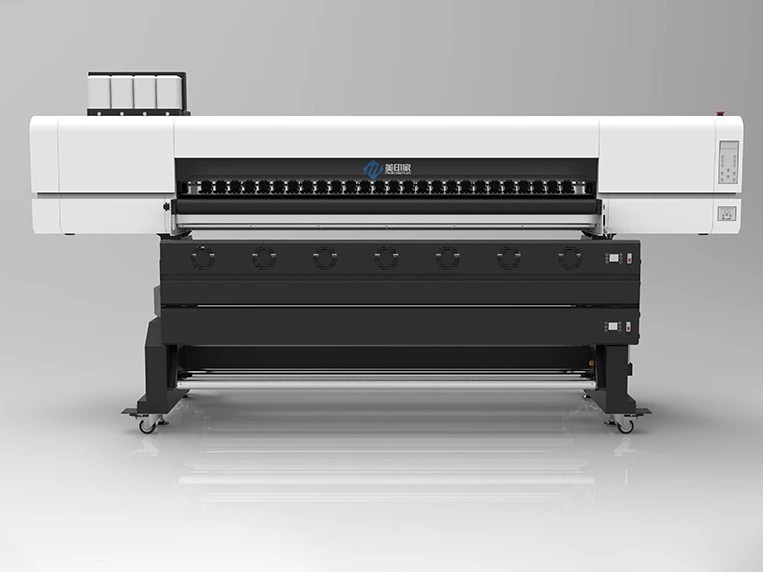

Printing and drying paper integrated digital printing machine

Size: L 3470 x W 1480 x H 1810 MM

Place of Origin: CHINA

Minimum order quantity: One unit

Color: Black and White

Type of material: Sublimation paper

Packaging: Wooden case / flight case

Delivery time: 7-15 working days

Model: Inkjet Printer

Transaction mode: T/T

Supply capacity: 200 units per month

Price: Negotiable

Product Details

Principle:Simply put, sublimation ink is printed on a specific paper by a machine in advance, and then through this paper, the pattern on the paper is transferred to the cloth to be printed with high temperature and high pressure, and the whole transfer printing process is completed.

Product Highlight

Product parameter

|

Print Nozzle |

EPSON-I3200 A1 |

|

Print Accuracy/speed |

4pass:330m2/hour |

|

Maximum width |

1920 MM |

|

Printer |

USB 3.0 |

|

RIP Software |

Maintop6.1 |

|

Drying system |

Drying system(standard parts) |

|

Powder |

AC110V+/-10% |

|

Operation Environments |

Temperatur:20℃-30℃ |

|

Printer powder |

Drawing 600w, front and back heating 800w, dryer 10000w |

|

Height of worktable |

1062 MM |

|

Dimensions of printer |

L 3350 x W 1260 x H 1650 MM |

|

Dimensions of packing |

L 3470 x W 1480 x H 1810 MM |

|

Ink capacity/Ink tank volumn |

3 L |

|

Net weight |

500 KG |

|

Gross weight |

560 KG |

|

High Printing quality |

Three intelligent eclosion print function:VSD technology |

|

Media Heater |

Pre/Post Heater |

Professional Features

Production process

1.Computer drawing, design pictures

2.Print pattern on hot transfer paper

3.Through the hot press, Press the pattern on the heat transfer paper onto the cloth

Product application

As a typical clean production printing and dyeing process, digital printing has been recognized and adopted by major enterprises, and has become the primary choice to replace traditional printing. As an emerging printing method, it is mainly used in curtains, sofa fabrics, clothes, scarves, cushions, etc. with the advantages of high efficiency, low proofing cost, good printing effect and less pollution.

faq

Preparation Before Shipment

● 100% Inspection of Shipment

● One-Site Testing And Commissioning